Wodula mphero wochita bwino kwambiri amatha kumaliza katatu kuchuluka kwa zida wamba munthawi yofanana ndikuchepetsa kugwiritsa ntchito mphamvu ndi 20%. Izi sizongopambana zamakono, komanso lamulo lopulumuka pakupanga zamakono.

M'magawo opangira makina, kumveka kwapadera kwa ocheka mphero akumalumikizana ndi zitsulo ndiye nyimbo yoyambira yopanga zamakono.

Chida chozungulira ichi chokhala ndi m'mphepete zingapo chimapanga chilichonse, kuyambira tizigawo tating'onoting'ono tokhala ndi foni yam'manja mpaka zida zazikulu zandege pochotsa zomwe zili pamwamba pake.

Pamene makampani opanga zinthu akupitilira kupititsa patsogolo kulondola kwambiri komanso kuchita bwino kwambiri, ukadaulo wodula mphero ukusintha mwakachetechete - chodulira cha bionic chopangidwa ndi ukadaulo wosindikiza wa 3D ndi 60% wopepuka, koma moyo wake ukupitilira kuwirikiza kawiri; ❖ kuyanika kumawonjezera moyo wa chida ndi 200% pokonza ma alloys otentha kwambiri.

I. Milling cutter Basics: tanthauzo ndi core value

Wodula mphero ndi chida chozungulira chokhala ndi mano amodzi kapena angapo, omwe amachotsa motsatizana komanso modukizadukiza katundu wa workpiece. Monga chida chapakati pa mphero, imagwira ntchito zofunika kwambiri monga kukonza ndege, masitepe, ma grooves, kupanga malo, ndikudula zogwirira ntchito.

Mosiyana ndi kudula nsonga imodzi potembenuza, odula mphero amawongolera kwambiri makinawo podula malo angapo nthawi imodzi. Kuchita kwake kumakhudza mwachindunji kulondola kwa workpiece, kumaliza pamwamba, komanso kupanga bwino. M'munda wazamlengalenga, wodula mphero wochita bwino kwambiri amatha kupulumutsa mpaka 25% ya nthawi yopanga popanga zida zamapangidwe a ndege.

Pakupanga magalimoto, odulira mphero molondola amatsimikizira kulondola koyenera kwa zigawo zikuluzikulu za injini.

Phindu lalikulu la odula mphero wagona pakuphatikiza kwawo kusinthasintha komanso kuchita bwino. Kuchokera pakuchotsa zinthu mwachangu pakuchita roughing mpaka kuchiza pamwamba pamakina abwino, ntchitozi zitha kumalizidwa pa chida chamakina chomwechi pongosintha ma cutter osiyanasiyana, kuchepetsa kwambiri ndalama za zida ndi nthawi yosinthira kupanga.

II. Mbiri yakale: kusinthika kwaukadaulo kwa odula mphero

Mbiri yachitukuko cha odula mphero ikuwonetsa kusintha kwaukadaulo pamakampani onse opanga makina:

1783: Katswiri wa ku France René adapanga chodulira mphero yoyamba padziko lonse lapansi, ndikutsegula nyengo yatsopano yodulira mano ambiri.

1868: Chitsulo cha aloyi cha Tungsten chidayamba kukhalapo, ndipo liwiro lodulira lidaposa mita 8 pamphindi kwa nthawi yoyamba.

1889: Ingersoll anapanga chodula mphero ya chimanga (spiral milling cutter), ndikuyika tsambalo mu thupi la ok cutter, lomwe linakhala chitsanzo cha wodula chimanga wamakono.

1923: Germany anapanga carbide yopangidwa ndi simenti, yomwe inawonjezera liwiro la kudula ndi kuwirikiza kawiri kuposa la zitsulo zothamanga kwambiri.

1969: Patent yaukadaulo waukadaulo wakuyika mpweya wamankhwala idaperekedwa, ndikuwonjezera moyo wa zida ndi nthawi 1-3.

2025: Odula a Metal 3D-osindikizidwa a bionic mphero amakwanitsa kuchepetsa kulemera kwa 60% ndikuwonjezera moyo wawo, ndikudutsa malire achikhalidwe.

Zatsopano zilizonse muzinthu ndi zomanga zimayendetsa kukula kwa geometric pakuchita bwino kwa mphero.

III. Kusanthula kwathunthu kwamagulu a milling cutter ndi mawonekedwe ogwiritsira ntchito

Malinga ndi kusiyana kwa kapangidwe ndi ntchito, odula mphero akhoza kugawidwa m'mitundu iyi:

| Mtundu | Makhalidwe amapangidwe | Zochitika Zoyenera | Makampani Ogwiritsa Ntchito |

| Zomaliza | Kudula m'mphepete pa nkhope zonse zozungulira ndi kumapeto | Groove ndi sitepe pamwamba processing | Kupanga nkhungu, makina ambiri |

| Wodula nkhope | Nkhope yayikulu yokhala ndi masamba ambiri | Large pamwamba mkulu-liwiro mphero | Chida cha silinda yamagalimoto ndi zigawo zamabokosi |

| Wodula mbali ndi nkhope | Pali mano mbali zonse ndi circumference | Precision groove ndi masitepe processing | hydraulic valve block, njanji yowongolera |

| Mapeto a mpira | Hemispherical kudula mapeto | 3D pamwamba processing | Masamba a ndege, mapanga a nkhungu |

| Wodula chimanga | Kukonzekera kozungulira kwa zoyikapo, malo akuluakulu a chip | Kuthamanga kwambiri kwa mapewa, kukwera kwakuya | Zigawo zazamlengalenga |

| Wodula masamba a mphero | Magawo oonda okhala ndi mano angapo komanso ngodya zokhota zachiwiri mbali zonse ziwiri | Kudzikuza mozama ndikulekanitsa | Magawo oonda okhala ndi mano angapo komanso ngodya zokhota zachiwiri mbali zonse ziwiri |

Mtundu wa zomangamanga umatsimikizira chuma ndi ntchito

Zowonjezerawodula mphero: Thupi lodula ndi mano amapangidwa molumikizana, ndi kukhazikika bwino, oyenera kuwongolera m'mimba mwake pang'ono

Zodula mphero zolondolera: zotsika mtengo zoyikapo m'malo mwa chida chonsecho, zoyenera kuchitira roughing.

Wodula mphero wowotcherera: nsonga ya carbide yowotcherera ku thupi lachitsulo, nthawi yachuma koma yocheperako

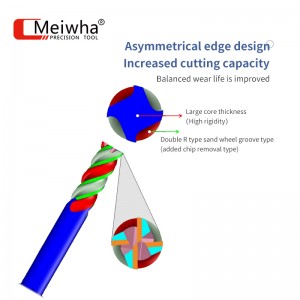

3D yosindikizidwa ya bionic: kapangidwe ka zisa zamkati za zisa, kuchepetsa kulemera kwa 60%, kukana kugwedezeka kwamphamvu

IV. Upangiri Wosankha Sayansi: Zofunikira Zofananira Zofunikira pakukonza

Kusankha chodulira mphero kuli ngati dokotala akukulemberani mankhwala - muyenera kupereka mankhwala oyenerera kuti mukhale ndi matenda oyenera. Zotsatirazi ndi zofunikira zaukadaulo pakusankha:

1. Kufananiza m'mimba mwake

Kudula mozama ≤ 1/2 chida m'mimba mwake kuti mupewe kutenthedwa ndi kupindika. Mukakonza mbali zowonda zokhala ndi mipanda ya aluminiyamu, ndikofunikira kugwiritsa ntchito mphero yaying'ono yocheperako kuti muchepetse mphamvu.

2. Kutalika kwa tsamba ndi kuchuluka kwa masamba

Kudula kwakuya ≤ 2/3 ya kutalika kwa tsamba; Pakukankha, sankhani masamba 4 kapena ochepa kuti mutsimikizire malo a chip, ndipo pomaliza, sankhani masamba 6-8 kuti muwongolere bwino.

3. Kusintha kwa zida za zida

Chitsulo chothamanga kwambiri: cholimba kwambiri, choyenera kudula kosokoneza

Cemented carbide: kusankha kwakukulu, kuuma koyenera komanso kulimba

Ceramics/PCBN: Kukonza mwatsatanetsatane kwa zinthu zolimba kwambiri, kusankha koyamba kwachitsulo cholimba

Kupaka kwa HIPMS: Kupaka kwatsopano kwa PVD kumachepetsa m'mphepete mwake ndikuwonjezera moyo ndi 200%

4. Kukhathamiritsa kwa geometric parameter

Helix angle: Mukakonza chitsulo chosapanga dzimbiri, sankhani ngodya yaying'ono ya helix (15 °) kuti muwonjezere mphamvu yakutsogolo.

Ngongole: Pazinthu zolimba, sankhani ngodya yayikulu (> 90 °) kuti muwonjezere chithandizo

Akatswiri amakono amatsutsidwabe ndi funso losatha: momwe angapangire kudula zitsulo kukhala kosalala ngati madzi oyenda. Yankho lagona pa ntchentche zanzeru zomwe zikuwombana pakati pa lupanga lopota ndi luntha.

[Lumikizanani nafe kuti mupeze njira zodulira ndi mphero]

Nthawi yotumiza: Aug-17-2025