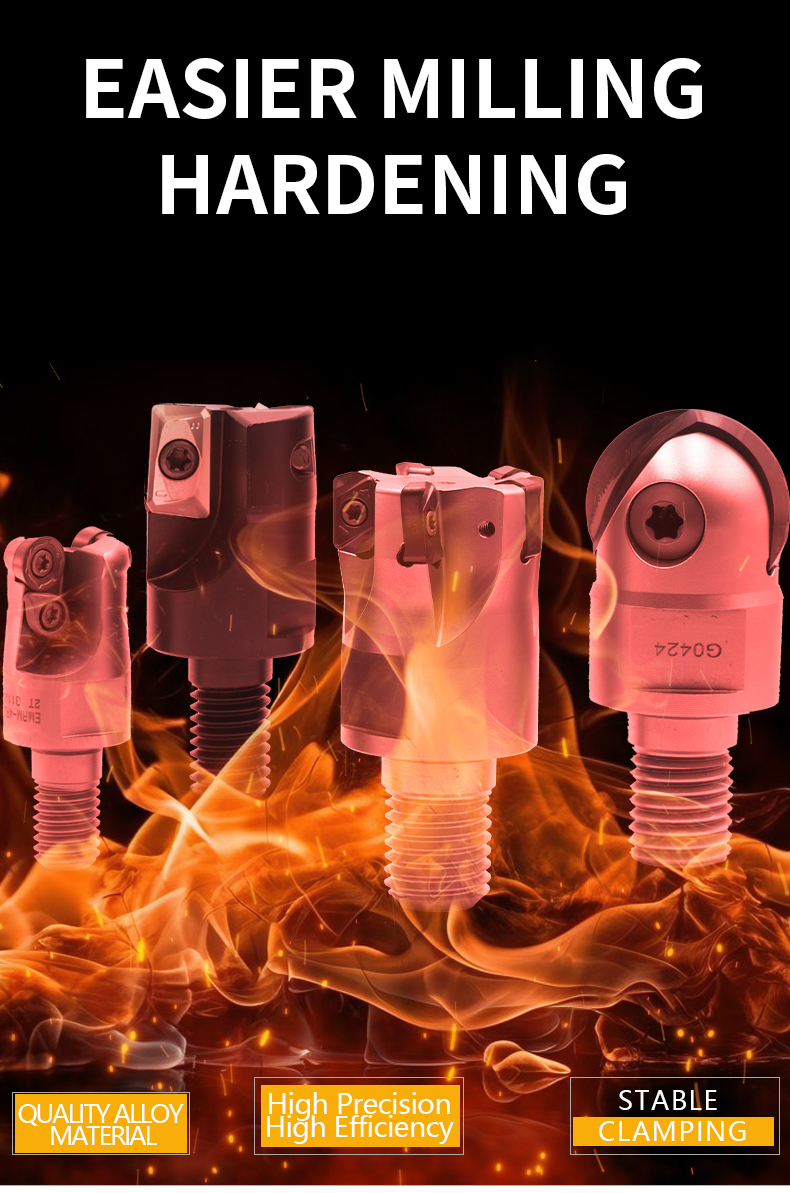

Shell Mill Cutter

Muzigwiritsa Ntchito Liti Shell Mill?

A Shell Mill nthawi zambiri amagwiritsidwa ntchito pazifukwa izi:

Kugaya Pamwamba Kwakukulu:Zigayo za zipolopolokukhala ndi ma diameter okulirapo, kuwapangitsa kukhala abwino pogaya madera akuluakulu mwachangu.

Kuchulukirachulukira: Mapangidwe awo amalola kuyika kochulukirapo komanso kuchuluka kwa chakudya, kupititsa patsogolo zokolola.

Kusinthasintha: Zida zitha kusinthidwa mosavuta, kupangazipolopolozosunthika pazinthu zosiyanasiyana komanso zomaliza.

Kumaliza Bwino Kwambiri: Kuchulukirachulukira kwa mbali zodulira nthawi zambiri kumabweretsa malo omalizidwa bwino.

Mtengo Wogwira Ntchito: Ngakhale kuti mtengo wake ndi wokwera kwambiri, kuthekera kosinthira zoyikapo m'malo mwa chida chonse kumatha kupulumutsa ndalama pakapita nthawi.

Ubwino wa Shell Mill

Kusinthasintha - Mphero za Shell zimatha kuchita pafupifupi mtundu uliwonse wa ntchito zotumphukira kapena slot. Kusinthasintha kwawo kumapangitsa chida chimodzi kuti chipeye malo athyathyathya, mapewa, mipata, ndi mbiri. Izi zitha kuchepetsa kuchuluka kwa zida zomwe zimafunikira m'sitolo.

Mtengo Wochotsa Zinthu - Malo akulu odulira a zipolopolo amatanthauza kuti amatha kuchotsa zinthu mwachangu kuposa mphero zomaliza. Mitengo yawo yapamwamba yochotsa zitsulo imawapangitsa kukhala oyenerera bwino kudulidwa movutikira komanso kugwiritsa ntchito makina olemera.

Kudula Kokhazikika - Mphepete zazikulu komanso kusasunthika kwa matupi a mphero kumapereka kudula kokhazikika, ngakhale kuzama kwa axial kodulidwa. Zigayo za zipolopolo zimatha kudulidwa molemera popanda kupotoza kapena kuyankhula.

Chip Control - Zitoliro zodulira zipolopolo za zipolopolo zimapereka chipolopolo chogwira ntchito ngakhale mphero zakuya kapena matumba. Izi zimawathandiza kuti azitsuka mphero popanda mwayi wochepa wodula chip.

Kuipa kwaChipolopolo:

Kugwiritsa Ntchito Pang'onopang'ono: Monga mphero zakumaso, mphero za zipolopolo zimagwiritsidwa ntchito makamaka popera kumaso ndipo mwina sizingakhale zoyenerera tsatanetsatane kapena zovuta kugaya.

Mtengo: Makina opangira zipolopolo amathanso kukhala ndi mtengo wokwera chifukwa cha kukula kwake komanso zovuta zake.

Imafunika Arbor: Mphero za zipolopolo zimafuna malo opangirako, zomwe zimawonjezera mtengo wonse komanso nthawi yokhazikitsa.

Zosankha za Shell Mill Tool Selection

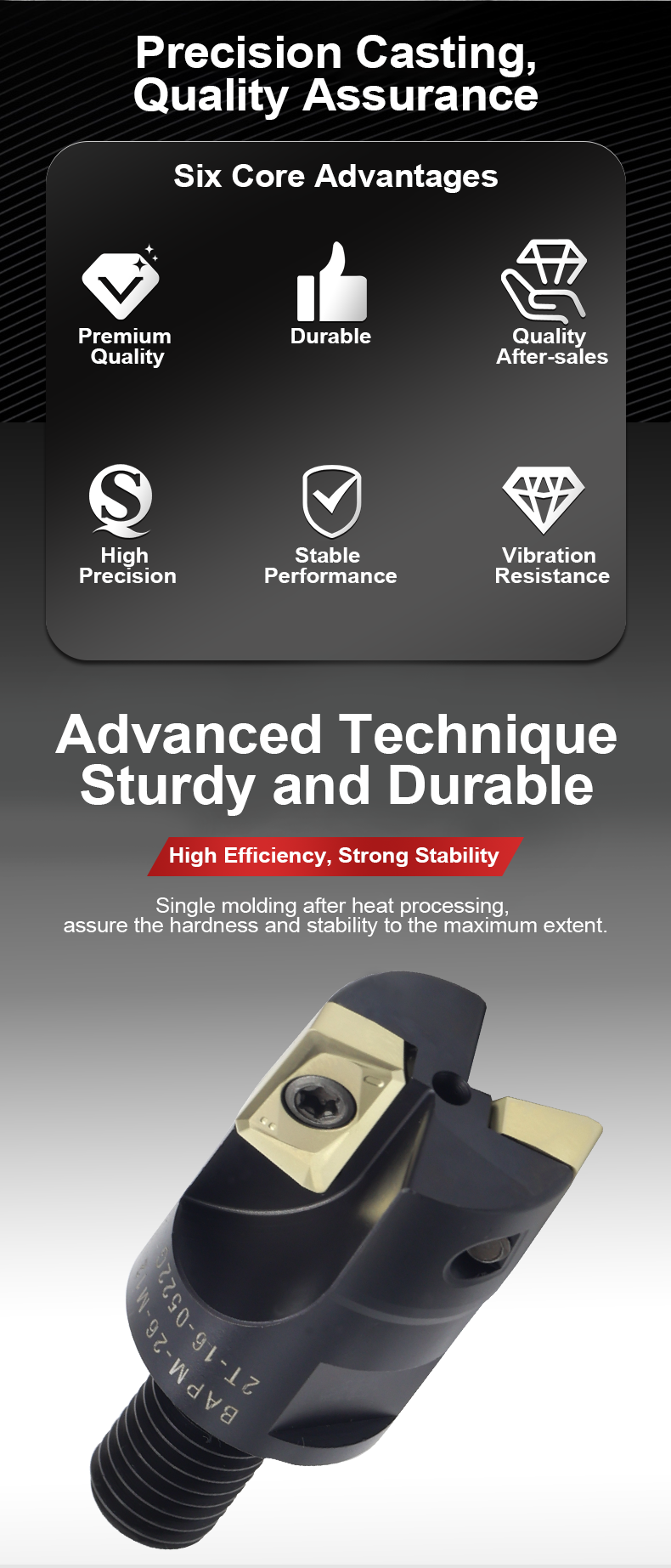

Cutter Material - Mphero za zipolopolo za Carbide zimapereka kukana kwabwino kwa zida zambiri. Zitsulo zothamanga kwambiri zitha kugwiritsidwanso ntchito koma zimangochepetsa kuuma kwa zinthu.

Chiwerengero cha Mano - Mano ochulukirapo adzapereka kumaliza kwabwino koma mitengo yotsika ya chakudya. Mano 4-6 ndi ofala kukhuta pomwe mano 7+ amagwiritsidwa ntchito pomaliza/kumaliza.

Helix Angle - Kutsika kwa helix (madigiri 15-30) kumalimbikitsidwa kuti zikhale zovuta kupanga makina ndi mabala osokonezeka. Ma angle a helix apamwamba (madigiri 35-45) amachita bwino pogaya zitsulo ndi aluminiyamu.

Kuwerengera kwa Flute - Mphero za zipolopolo zokhala ndi zitoliro zambiri zimalola kuti chakudya chikhale chokwera koma kupereka malo oti chip chisamuke. 4-5 zitoliro ndizofala kwambiri.

Insets vs Solid Carbide - Odula mano olowetsedwa amalola kulondolera zoyikapo zosinthidwa. Zida zolimba za carbide zimafunikira kugaya/kunola zikavala.